CORRECTING U-JOINT OPERATING ANGLES

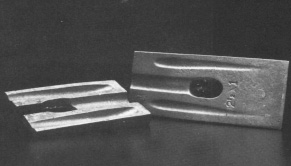

The recommended method for correcting severe u-joint operating angles depends on the vehicle suspension or driveline design. On vehicles with leaf springs suspension, thin wedges called axle shims can be installed under the leaf springs of single axle vehicles to tilt the axle and correct u-joint operating angles. Wedges are available in a range of sizes to change pinion angles. On vehicles with tandem axles, the torque rods can be shimmed. Torque rod shims rotate the axle pinion to change the u-joint operating angle. A longer or shorter torque rod may be available from the manufacture if shimming is not practical. Some torque rods are adjustable.

The recommended method for correcting severe u-joint operating angles depends on the vehicle suspension or driveline design. On vehicles with leaf springs suspension, thin wedges called axle shims can be installed under the leaf springs of single axle vehicles to tilt the axle and correct u-joint operating angles. Wedges are available in a range of sizes to change pinion angles. On vehicles with tandem axles, the torque rods can be shimmed. Torque rod shims rotate the axle pinion to change the u-joint operating angle. A longer or shorter torque rod may be available from the manufacture if shimming is not practical. Some torque rods are adjustable.

As a general rule, the addition or removal of a 1/4″ shim from the rear torque arm will change the axle angle approximately 3/4 of a degree. A 3/4 of a degree change in the pinion angle will change the u-joint operating angle about 1/4 of a degree.

Always take the time to call the vehicle manufacturer if there are unusual u-joint operating angle problems.

WHAT CAUSES U-JOINT OPERATING ANGLES TO CHANGE

- Suspension changes caused by: worn bushings in the spring hangers, worn bushings in the torque rods incorrect airbag height

- Revisions in components of the driveline

- Stretching or shortening the chassis

- Adding an auxiliary transmission or transfer case in the main driveline

- Worn engine mounts

- Raising or lowering of the vehicle

DRIVESHAFT BRAKE

When a driveshaft brake is used, care must be taken to see that the brake drum is properly piloted, runs true and is in balance.

Visit Drivetrain Specialists at www.drivetrain.com or you can call the order desk at 1-800-216-1632 to talk to a knowledgeable technician. If you are considering purchasing parts from drivetrain.com and have questions contact the Tech line at 1-702-876-3100 or send e-mail. Drivetrain Specialists of Las Vegas – Las Vegas NV, 89102