Steel vs. Fiberglass Jeep Bodies: Pros, Cons, and Considerations At some point, most Jeep owners, especially those working on older CJ restorations, end up facing the same decision: steel or fiberglass? Whether your original tub is flaking away like a stale croissant or you just want to shed some weight, the choice between a steel and fiberglass body can steer your entire build in a different direction.

Let’s break it down.

Steel Bodies

The factory option. The purist’s favorite. The rust-prone reality.

Pros:

- Authenticity – If you’re going for a proper restoration, steel is the only way. It looks right, sounds right, and rusts again just like it should.

- Strength – Steel absorbs impact better than fiberglass. It bends, but it usually doesn’t shatter. If you wheel hard, this matters.

- Ease of welding – Got rust? Got a torch? Steel can be patched and reworked in any decent home garage with a welder and some patience.

Cons:

- Rust – Steel and moisture get along about as well as Jeeps and speed bumps. If you’re not diligent with undercoating and drainage, your floorboards will slowly return to the Earth. It really hurts when you spend the money on a new replacement body and it starts to rust. Rust proofing is worth every penny.

- Weight – Steel bodies are usually heavier than fiberglass, but not always by much depending on the brand of the fiberglass body. For trail rigs, that extra weight can mean more strain on suspension and drivetrain components.

- Cost – New steel tubs aren’t cheap. NOS or aftermarket steel can get pricey, and shipping something that size isn’t doing your wallet any favors either.

Gary’s 1974 CJ-5 is near perfect with it’s replacement steel body.

Fiberglass Bodies

Typically Lighter. Rust-proof. Slightly less “Jeep-y.”

Pros:

- No rust – Period. Fiberglass won’t corrode, which is why it’s a favorite in coastal regions where salt eats steel for breakfast. Scratches, dings and drill holes will not cause any rust, never.

- Weight savings – Depending on the tub, fiberglass can be quite a bit lighter than steel. Less weight = easier on axles, brakes, and MPG. Some fiberglass bodies integrate steel and wood within it which adds weight. Manufacturers should be able to give you specs on the weight.

- Consistency – Fiberglass tubs come out of a mold, so body panels tend to be straight. You won’t fight the factory’s “tolerances” like you do with old steel. But typically the mold is used over and over and was taken from an original Jeep body. Any imperfections in the model body will be in every fiberglass body.

Cons:

- Cracks under stress – Fiberglass doesn’t dent, it cracks. Hit a rock the wrong way and you could be into patchwork and reinforcement.

- Harder to repair in the field – If you’re out on the trail, it’s easier to hammer steel back into place than to fiberglass a corner together. If you bust off a piece, keep it and glue it all back together when you get home.

- Mounting issues – Older fiberglass tubs often needed tweaking to get everything to line up right. Newer ones are better, but you still might have to redrill or shim something to get a perfect fit.

- Grounding problems – Steel conducts electricity. Fiberglass doesn’t. That’s great for insulation, but bad for wiring grounds especially tail lights and fuel senders. You will quickly learn of the amount of extra wire needed for all the grounds.

So, Which One?

Fiberglass holds a special place for the CJ crowd since so many Jeeps were equipped with replacement bodies in the 80’s and 90’s. It’s almost an awesome throw back to days past. Using a glass body on a CJ isn’t blasphemy in the Jeep community like it could be in other vehicle makes.

It depends. If you’re building a period-correct CJ with plans for local shows and weekend drives, steel makes sense. If you’re on the East Coast and tired of replacing floor pans far too often, fiberglass might be your new best friend. For trail rigs, the debate gets tougher do you want the impact resistance of steel or the weight savings of fiberglass?

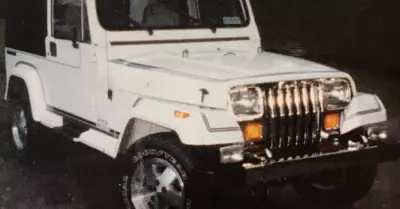

The jeepfan.com 1978 CJ-5 has been equipped with a fiberglass body from the now defunct AJ’s in Jersey Shore, PA. Their bodies were once considered top of the line, we didn’t install the body on our Jeep but the body has held up great in the near 30 years that Jeep has been part of our stable. There are times a steel body would be desirable but we have little complaint with the fiberglass. You can see that the Jeep has stayed looking the same over time, even after 10 years of regular off road use.

Either way, pick a tub that matches your tools, your skills, and your plans. Just know that whichever you choose, it’ll still leak in the rain and turn heads in the Home Depot parking lot. Just like a real Jeep should.

There are still some fiberglass body makers out there, Shell Valley seems to be the most popular

Willys Overland probably sells the best replacement steel bodies, their Repli-Tub is worth the price to get your Jeep close to how it came from Toledo.

Leave a Reply