The rear corners of a Jeep Wrangler TJ are more vulnerable than most owners realize. The TJ Unlimited has an extended section of the rear corner which makes it further exposed. Whether you’re navigating tight wooded trails, sliding past boulders, or simply loading gear in the driveway, the factory sheet metal back there is thin and easy to crease. Steel corner guards solve that problem while adding a healthy dose of rugged style in the process.

Why Steel Corner Guards?

1. Trail Armor for the Rear Tub

The factory TJ body is made of relatively light-gauge steel. One good encounter with a tree, rock, or even a shopping cart in the wrong spot can dent it. Steel corner guards, typically made from 1/8″ or thicker plate steel, act as a full armor panel that takes the abuse before your tub does.

2. Rust Protection

Even if your Jeep never sees off-road duty, corner guards cover an area prone to chips and scratches from cargo loading, spare tire changes, and bumper swaps. Covering these corners helps prevent rust from starting in these high-wear spots.

3. Visual Upgrade

Steel corner guards give the TJ a more aggressive, purpose-built look. They pair especially well with aftermarket bumpers, tire carriers, and rocker guards, making the whole Jeep appear more cohesive and trail-ready.

4. Mounting Platform

Many steel corner guards come pre-drilled for accessories like tail light upgrades, CB antenna mounts, or even extra rear lighting. This makes them a functional platform as well as protection.

Installation Overview

Installing steel corner guards on a TJ is a straightforward DIY project, but it does require patience and precise drilling.

Tools & Materials You’ll Need:

- Steel corner guards (pre-cut for TJ) – Ours are Poison Spyder which are no longer available but the concept is the same.

- Drill and bits (including step bit for larger holes)

- Rivnut tool or stainless hardware (depending on kit)

- Tape measure & masking tape

- Marker or scribe

- Rust-inhibiting primer and touch-up paint

Step-by-Step:

Prep the Jeep

Remove tail lights, license plate bracket, and any accessories that interfere with the rear corners. Clean the surface thoroughly — dirt and rust left behind will only get sealed in.

Test Fit the Panels

Hold the corner guards in place and align them with the tub lines. Most kits are cut to fit tightly around the wheel opening and tailgate, so some wiggling is normal.

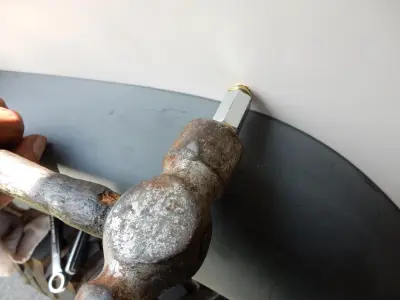

Mark & Drill Holes

Once aligned, use masking tape to hold the guards in place. Mark all mounting holes, then remove the panel and drill the tub. If the kit uses rivnuts, follow the included size requirements. Always paint the edges of drilled holes to prevent future rust. We also fixed/sealed some rust and painted at the edge of the corner near the fender flare to hide the small strip of white body that is exposed behind.

Paint

The rear corners we used came unpainted and after everything was fitted a nice coat of rattle can black was applied.

Install Hardware

If using rivnuts which are only used in certain places of the corners, install them first. Then bolt the corner guards in place using stainless steel hardware. Work from the center outward to ensure even fitment.

Reinstall Accessories

Reinstall tail lights, license plate bracket, and any removed hardware. This is also a great time to upgrade to LED tail lights if the kit supports them.

Cost & Final Thoughts

Quality steel corner guard kits for a TJ typically run $200–$350, depending on brand and finish. Powder-coated versions save painting time but can cost more, while raw steel allows you to color-match or custom coat.

For a Jeep that actually gets used, steel corner guards aren’t just cosmetic they’re insurance against expensive bodywork. The installation is a one-time effort that can save you from countless dents, rust repairs, and “should have” moments after a tight trail squeeze.

The black corners on the white Jeep look very nice and break up all the white paint. Soon after this project we upgraded the rear (broken) tail lights with some nice LED ones, take a look.

Leave a Reply