If you’ve driven a Jeep CJ with a mechanical clutch linkage—especially off-road—you know the struggle. Binding linkages, misalignment from frame flex, and a stiff, inconsistent pedal feel can make crawling over rocks more of a workout than it should be. That’s where a hydraulic clutch conversion comes in. We recently upgraded the jeepfan.com 1978 CJ-5 with this mod and can honestly say it’s a 100% improvement.

Why Go Hydraulic?

The stock mechanical linkage works… until it doesn’t. On uneven terrain, the clutch linkage can bind or even pop off due to frame twist or engine movement. Hydraulic systems, on the other hand, are self-adjusting and don’t care if the frame is flexed or not. Plus, pedal feel is smoother and more predictable. It’s a win all around.

The Parts

There used to be kits for a hydraulic clutch conversion in a CJ but since the newest CJ is over 35 years old kits have become scarce so some improvisation and fabrication is needed. Here’s our parts list.

- Wilwood 3/4″ bore Master Cylinder – Finding a “factory” master cylinder is a challenge. If you look around at what’s available you quickly learn that there seems to be no standard to a factory replacement. All of the parts vary a bit. The Wilwood is a better product in every way, it’s consistent and serviceable.

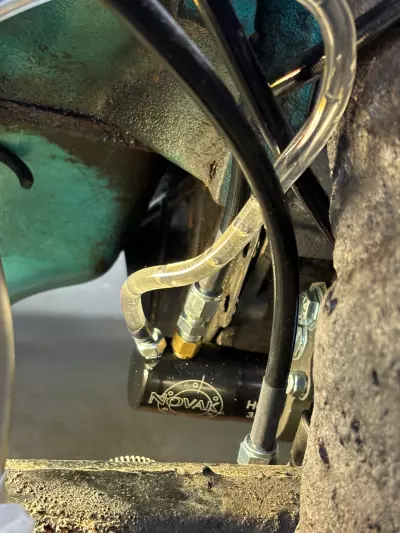

- Novak AMC Slave Cylinder Mounting Bracket and 3/4″ Bore Slave cylinder – Novak never disappoints..this bracket is easily installed and will mount their slave cylinder perfectly. They offer two size bores in their slaves. We matched the slave to the master for a 1:1 ratio.

- All Star Performance Brake Line – If you linger around street rod (and the like) forums you will see many using braided brake lines over hard steel. There’s benefits to steel but the flexible lines make installation much easier.

- Some extra fittings – The slave uses an NPT style fitting when the braided line uses AN style. A small fitting adapter is easy to get that will work perfectly.

This hydraulic clutch conversion can bolt right into some years of the CJ firewall and pair up with a variety of transmission setups including T-176, T-150, T-18, and even some swaps.

The Install

Like any good Jeep upgrade, we started by yanking out the old clutch linkage. This project came along side a power brake conversion. A couple of cotter pins, a few bolts, and the factory mess was history. The jeepfan CJ had some custom work done with the factory linkage to include rod ends over the factory metal on metal rod, this was still not great.

Master Cylinder

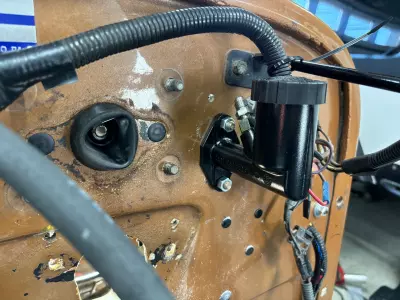

The jeepfan.com CJ has a fiberglass body which usually has no holes for anything when new meaning that everything needs to be custom. We needed to cut a hole in the firewall for the master cylinder to mount to. Since we were in the process of adding power brakes it was a good time to cut holes since much of the hardware in that area was already out of the way.

After a considerable amount of measuring a pilot hole was drilled followed by the hole saw. A quick test fit showed we did a good job and we proceeded to drill the holes for the mounting bolts. With the master in place we needed to drill a hole in the clutch arm to bold the master’s rod end to. Some Jeeps, depending on the year could have a provision for this but the 78 never had a hydraulic clutch option.

After lining everything up we needed to remove the entire pedal assembly to drill a hole. This isn’t a pleasant task but as we said before this was part of a brake conversion so the area was all apart already. Try to keep the mounting hole higher on the pedal arm to allow good movement of the pedal. A lower hole will reduce the length of the pedal throw and make the pedal feel stiffer.

After the pedal assembly was back in we made sure everything lined up nicely and even tested the pedal throw, all seemed good except there just felt like some reinforcement was needed to support the master cylinder on the fiberglass firewall.

We fabricated a steel mounting reinforcement to squeeze into the tight area. With that completed the master could be finally bolted up.

Slave Cylinder

The Novak mounting bracket for AMC engines shares a few of the bell housing bolts and positions the slave in the proper place. The thick steel bracket has a few options and allows some adjustment. The Novak mount is designed for round threaded mount style slave cylinders. The Novak slave will fit this hole perfectly and is worth the investment. The Novak slave is well built and like the Wilwood master, it’s fully serviceable.

The slave should be mounted and adjusted to have a small amount of clearance for the throw out bearing. By moving the throw out arm to feel the bearing contact the clutch you can get a feel for where contact happens. Adjust the slave arm to provide this clearance so the bearing is not constantly riding the clutch causing wear.

Hydraulic Line

Routing the hydraulic line down to the slave was a breeze—thanks to the All Star Performance braided line. The braided line was routed to avoid hot exhaust components and the steering shaft so there’d be no worrying about heat or abrasion.

Bleeding, Pedal Feel and Testing

With the system bled and filled with fresh DOT 3 brake fluid, we did some testing. The difference? Night and day. The clutch pedal now has a light, linear feel and engagement is much more controlled. No more jerky starts or struggling to modulate in tight spots. To be honest it took a bit of time to adjust to the new feel since there were many years dealing with the feel of the mechanical linkage.

Final Thoughts

If you’re still running a mechanical clutch on your CJ, it might be time to consider doing a hydraulic clutch conversion. Whether you’re wheeling hard or just cruising to the ice cream shop, this upgrade adds real drivability and reliability. It’s one of those mods that makes you wonder why you didn’t do it sooner.

Wilwood GS Compact Master Cylinder 260-15098 – Summit Racing