A local guy that does bench rebuilds in town recommended that Steve

find a good runner over a core even though the transmission would need

to be rebuilt. The thinking is that if any major parts are damaged in

a core, the cost of new parts will far exceed the cost of a good

runner. Steve purchased a running T-18, but the shift lever was

missing. It seems that the shift levers and the input bearing

retainers are some of the most commonly damaged parts on Ford T-18s

and this one was slightly canabilized.

Most Ford T-18 conversion kits I've seen replace the main shaft and

the tail housing of the transmission, so when you searching for a Ford

T-18 to swap into a CJ with a Dana 300, it is best to get the 2WD

version. The 2WD versions are generally cheaper than the 4WD versions

and the adapter kit bolts right on the 2WD version where the 4WD

version may need to have holes tapped in the case.

Ford T-18 bolted to AMC bell

housing with adapter for Dana 300

Steve dropped off his Ford T-18 and a conversion kit from Advanced

Adapters at a for a bench rebuild. Bench rebuilds are fairly

inexpensive, normally $150-$200 plus parts. New bearings were put in

this transmission and a synchro was replaced. It is well worth to

replace any questionable parts at this time.

Advanced Adapters makes a special pilot bushing for the conversion

that is AMC on the outside and Ford on the inside. It is not part of

the Ford T-18 conversion kit, so you will need to order it separtely.

You can make you own pilot bushing by taking a stardard Ford pilot

bushing and turning down the outside to the size of the outer large

hole in the crank shaft. I've had one custom made at a clutch shop

local, but there was no cost savings over the Advanced Adapters

bushing.

A standard pressure plate can be used for the conversion, you may

want to keep your old one if it is fairly new. Since pulling a

transmission is very time consuming, a new pressure plate is a good

idea if you haven't put in a new one in a while.

The Jeep T-150, T-18, T-176, SR-4, T-4, and T-5 all use a 1 1/8" 10

spline input shaft and the Ford T-18 uses a 1 1/16" 10 spline input

shaft. Your old clutch disk will not fit snuggly on the Ford input

shaft, so you will need to purchase a new disk. The disk can be a

regular 10 1/2" Ford disk (or 11" if you have an 11" clutch). The

Centerforce clutch disk #384180 is a 10 1/2" clutch that will fit the

Ford transmission.

Ford T-18 front view. Ford T-18s have a slightly different bolt

pattern than most Jeep T-18s. The drivers side lower bolt is lower

on the Ford version. The Ford pattern matches the T-150 and T-176.

The bell housing bolt pattern for the Ford T-18 is exactly the same as

the T-150 and the T-176 transmissions. The Jeep T-18 has one bolt hole

different, the bolt near the clutch fork is higher on the Jeep

version. The SR-4, T-4, and T-5 use a different bolt pattern.

Steve's Jeep had the bell housing that went with the T-5, so the

holes didn't line up quite right. If you drill carefully, a drill

press would help here, you can drill out the bolt pattern for the Ford

T-18 on one of these bell housings. The transmission can be tilted a

bit to the left or right, alignment on that plane is not critical. We

were trying to drill out the holes with a hand drill and messed up one

of the holes, so Steve purchased a used bell housing for $30 with the

proper bolt pattern. If you are going to drill the holes, make sure

you have the right size bit for the tap you are going to use to thread

them.

80s CJ-7 skid plate

modification to fit Ford T-18

Minor modifications are required to the skid plate to fit the larger

T-18. A notch needs to be cut in the leading edge of the skid plate to

allow room for the drain plug in the bottom of the T-18. The picture

on the left shows the modified skid plate with notch cut out. The

notch was cut with a regular circular hand saw with metal cutting

blade.

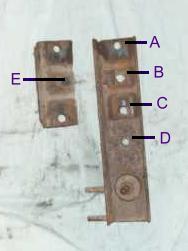

Modification to the stock CJ

mount bracket for T-18 installation.

On the transmission mount, Advanced Adapters supplies a aluminum

spacer block to mate the bolt holes in the bottom of the transmission

to transfer case adapter to the transmission mount. This spacer block

forces the transmission very close to the tub and causes a minor drive

shaft vibration with a 2 1/2" spring lift. Dropping the skid plate

would resolve the problem, but at the cost of ground clearance.

In order to set up the transmission mount with out losing ground

clearance, the transmission mount must be modified. It is easier to

take care of this before you install the transmission.

- Toss the spacer block in your scrap metal pile.

- Bolt the torque arm directly to the transmission to transfer

case adapter directly with the bolt hole on the drivers side (fig.

1, item D) and the limiting donut to the drivers side.

- Mark and drill the torque arm for the other hole (fig. 1, item

B) into the transmission to transfer case adapter. Bolt the torque

arm with both bolts to the transmission to transfer case adapter.

- Drill and tap the transmission to transfer case adapter for the

hole in the torque arm that falls between the two holes (fig. 1,

item C) that bolt into the adapter. This hole should be either for a

1/2" or 7/16" bolt. The transmission mount will bolt through the

torque arm into the transfer case adapter.

- Cut a small notch out of the middle of the transmission mount

with a circular hand saw (fig 1, item E). The notch needs to be

large enough for the head of the bolt.

- The passenget side bolt hole for the transmission mount remains

unchanged (fig. 1, item A).

If you are swapping in a Ford T-18 for a T-176 or T-150, the rear

drive shaft may need to be shortened and the front drive shaft may

need to be lengthed since the overall length of the Ford T-18 and

adapter is longer than the T-176. If you have an SR-4, T-4, or T-5, no

drive shaft modifications are required for the swap if you use the

Advanced Adapters kit.

Ford T-18 in a CJ-7 from in the cab

The shift lever for the Ford T-18 is in the same place as the shift

lever for the T-176 and T-150, but is several inches forward of the

shift lever for the T-5, T-4, and SR-4. For these transmissions, a

hole must be cut in the tunnel cover for the T-18 shift lever and the

old hole should be covered with sheet metal. If you have carpeting

over the tunnel, you'll end up with an extra hole in that as well. A

new boot is necessary, especially if you have the integrated

transmission and transfer case boot.

Depending on the source of you Ford T-18, you might need to heat

and bend the shift lever so it clears your console and dash. The T-18

in Steve's Jeep is from a '83 Ford pickup and it did not need any

bending. My Ford T-18 is also out of an '82 F-250 and the lever is

snug on console. I've had my T-18 pop out of reverse a couple of times

when there is a lot of flex, but it normally doesn't happen.

If you have a T-5, T-4, or SR-4, the position of the transfer case is

nearly unchanged. No modifications are necessary to the transfer case

linkage or the hole in the tunnel cover. Modifications may be

necessary to the tunnel cover when you are swapping out a T-176 or

T-150 because the transfer case lever will be repositioned slightly.

Most Ford T-18s I've seen come with a little pop-up breather. While

the transmission on the floor, it would be a good time to remove the

pop-up breather, remove the transmission top cover, and thread the

hole with a tap. A short barbed fitting can be installed to run a long

breather hose somewhere high. The hose can be tied into the transfer

case breather if your original transmission didn't have a breather

hose.

The easiest thing to do with the backup switch is cut the other end of

the plug out of the donor and splice it in. There aren't many styles

of backup switch, so your old plug may work with the Ford T-18. The

switch from you old transmission might even work in the Ford T-18.

None of those options worked for me, so I spliced in a 2 wire plug and

put soldered the wires to the Ford T-18 switch. After soldering the

wires on the switch, I filled it with RTV to keep it water proof.

You'll find a significant difference between the weight of the Ford

T-18 and your originally transmission. The transmissions used in 80s

Jeeps all have aluminum cases and weigh about 80 pounds or so. The

Ford T-18 weighs closer to 150 pounds dry. A good transmission jack

will help a great deal for installation.

Back view of T-18 converted for Dana 300

Side view of T-18 converted for Dana 300

Ford T-18 front view. Ford T-18s have a slightly different bolt

pattern than most Jeep T-18s. The drivers side lower bolt is lower

on the Ford version. The Ford pattern matches the T-150 and T-176.

Most of the problems with Steve's Ford T-18 swap were not directly

related to the swap itself. One big problem we had was Steve didn't

have a shift lever right off. This wasn't really much of a problem,

but we hadn't run the transmission through the gears until we had it

completely installed. It turned out one of the dogs popped off

somewhere along the way and we had to pull the entire thing and take

it back to the transmission guy. Shift your transmission through the

gears before you install it! The other problem we had was Steve

chunked a rear bearing on the test drive, completely unrelated, but it

meant Steves Jeep sat in my garage for an extra week or so.

The payoff in the end was big. The truck crawls much better and it

doesn't leak trans fluid on steep climbs like the T-5 tends to. Steves

crawl ratio went from 3.31*2.62*4.03 = 34.94:1 to 3.31*2.62*6.32 =

54.79:1. Reliability of the transmission is also greatly improved with

the heavy cast iron case and larger gears.

Thanks to Jeepin Joe Heinrich for the 2WD Ford T-18 picture. Thanks to

Predator 4 Wheel Drive for allowing some of the converted Ford T-18

pictures.