Drill Press Features

Drill presses are designated by the

maximum-diameter work piece, in inches,

that can be centered under the bit. To

understand how much a drill press can

handle, divide this number in half to

get the throat depth, or distance from

the bit to the support column at the

back of the machine. This dimension

indicates how far you can place a hole

from the edge of your work.

Most machines come with induction motors and deliver power through a belt running around a pair of stepped pulleys. In most cases, this provides five speeds. There are some models that allow constant variable speeds.

Chuck size for typical bench top units is 1/2 in. Chucks are mounted on tapered spindles--a tap with a mallet keeps the chuck in place and the tapered fit guarantees accuracy.

Drill press spindles run in a quill, or hollow shaft, that's designed to move up and down in the housing. Quill travel determines the maximum hole depth. Most units have a depth stop so that you can bore holes or counterbores to a uniform depth. Some machines have a quill lock that allows you to lock the spindle at any position within its range.

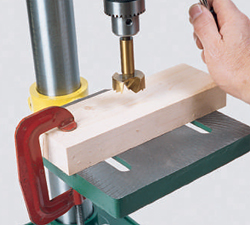

Typically,

drill press tables are small and reflect

the machine's heritage as a metalworking

tool that handles relatively small

work pieces. The average table size is

about 8-3/4 in. square, and the usual

design features slots for attaching

jigs, vises or the work itself to the

table. Our larger Delta machine has T

channels instead of slots, providing a

place for lubricant to collect when

working with metal. The slotted tables

are handier for woodworkers because they

make it easier to attach a large wooden

table to better support bigger work.

Typically,

drill press tables are small and reflect

the machine's heritage as a metalworking

tool that handles relatively small

work pieces. The average table size is

about 8-3/4 in. square, and the usual

design features slots for attaching

jigs, vises or the work itself to the

table. Our larger Delta machine has T

channels instead of slots, providing a

place for lubricant to collect when

working with metal. The slotted tables

are handier for woodworkers because they

make it easier to attach a large wooden

table to better support bigger work.

All drill press tables can pivot at their connection to the support column to handle angled boring. This feature also allows the tables to be accurately squared with the bit. However, we found that most tables were slightly out of square on a plane viewed from the side of the tool, where there is no adjustment. Most of our test machines have a crank-operated table lifting mechanism.